Power, rather than efficiency, was the aim for most steam locomotives.

#STEAM ENGINE WORKING SERIES#

Double and triple expansion engines forced expanding steam through a series of pistons before eventually letting the gas free, squeezing every ounce of energy from their fuel and allowing the transit of multiple oceans at a time. Many ocean liners were fitted with large marine steam engines, not only because of their great reliability but also because of their great efficiency.

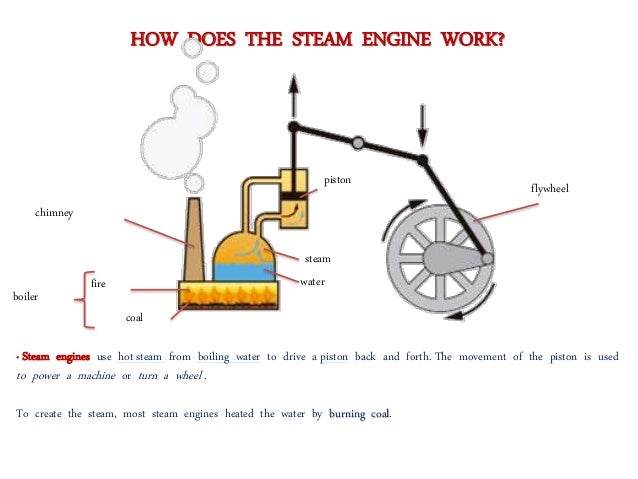

Different sizes and shapes of engines were soon being used to conduct small tasks such as churning butter in farm houses, pushing and pulling mechanical linkages through the oil fields of Pennsylvania, and spinning a cacophony of belt driven factories around the world. The complexity and diversity of steam engine design increased rapidly. High pressure steam engines were soon developed that used expanding steam, rather than condensing steam, to deliver more powerful and doubly efficient machines. It was this expansion that helped drive the Industrial Revolution. Steam soon began to replace the water wheel, allowing factories to be built far away from rivers. Known as the “atmospheric engine”, it utilized the condensation of steam to create a vacuum driven power stroke.

Thomas Newcomen, however, became the first inventor to harness the power of steam with a piston driven engine in 1712. Machines dating back to the time of the Greeks have used the qualities of steam to create motion. The most valuable characteristic of steam is that it occupies 1,700 times more volume in its boiled gaseous state than in its liquid water form (at an ambient pressure of one atmosphere).

0 kommentar(er)

0 kommentar(er)